Manufacturing Capabilities

Tryout

Tool tryout is controlled by our six technical advisors who share their experience with the die makers through the try-out process. The simulator, designer and advisor compare all data to make sure the conditions are optimal. Try-outs take place in our 1500T, 880T, 350T, 300T presses.

Machining

The CNC department has been fine-tuned with quick setup fixtures and a tool crib to optimize the machining time. Our machining workshop is comprised of nine CNC centers, two wire EDM machines, one three-axis and one six-axis laser, and many conventional stations to support the fabrication towards the assembly.

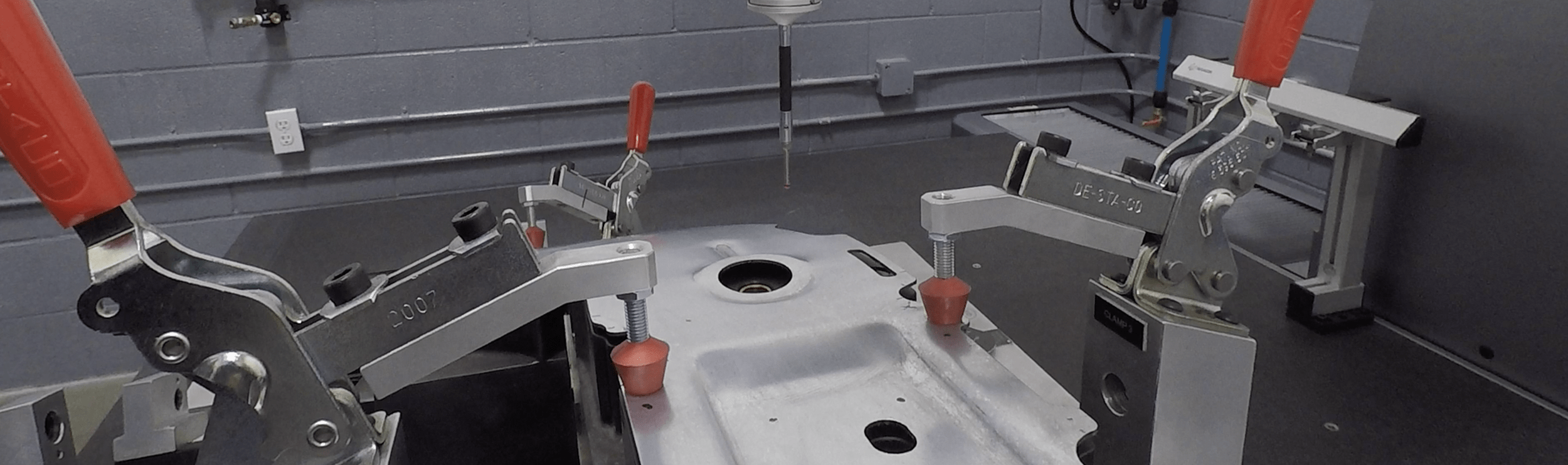

Assembly

The tool room area regroups all the necessary equipment to prepare the tools for the press. For each project, our designers and tool makers meet to ensure transfer of knowledge. Once the assembly is complete, there is a sign-off gate with the technical advisors / tool makers / designers. The assembly feedback returns to the design team.

Quality

Complete buy-off documents are produced depending on customer requirements from the CMM lab and quality department. Full layouts and GR&R (gage repeatability and reproducibility) studies are all prepared for the buy-off event.

Build Events

Part requirements, such as hard-form laser cut parts or first-off runs, are regular events before buyoff. This milestone is completed with the advisors once the CMM layouts have been approved with the customer. Parts will be shipped and tracked all the way to the required destination. Spectra Premium’s international shipping department shares its resources to certify this activity.